Views: 0 Author: Site Editor Publish Time: 2024-09-23 Origin: Site

When it comes to precision manufacturing, CNC lathes have revolutionized the industry. According to Parmar, P. N., Gondalia, V. R., & Mehta, N. C. (2014) CNC lathes stand out for their specialized design and ability to process larger workpieces with greater precision compared to conventional lathes. But which manufacturers dominate this market? In this article, we’ll walk you through the top 10 raised CNC lathe manufacturers you should know, from industry giants to innovators in high-precision machinery.

CNC lathe machines are a staple in modern manufacturing, streamlining complex machining processes. But what exactly is a CNC lathe machine? At its core, a CNC (Computer Numerical Control) lathe machine is a precision tool used to shape various materials—typically metal, wood, or plastic—by rotating the workpiece against cutting tools. The machine is controlled by a computer, making it more accurate and versatile than traditional lathes. If you're curious about how advanced manufacturing works, a CNC lathe is a prime example of cutting-edge technology in action.

A CNC lathe machine consists of several essential components:

Houses the spindle, the heart of the machine that holds and rotates the workpiece.

Provides support for longer workpieces during machining.

Moves along the machine's axis, holding and controlling the cutting tool.

Holds the material in place while it's rotated.

The interface where the operator inputs commands or loads the program. Understanding these components is crucial for anyone operating or working with CNC lathes.

Ever tried cutting a straight line with scissors? Not so easy, right? Now imagine trying to make ultra-precise cuts in metal or plastic by hand—basically impossible. CNC lathe machines, however, excel at precision. They follow exact instructions fed through computer software, meaning they can make the same cut 100 times and get it right every single time. No human error, no slight deviations.

Time is money, and in manufacturing, this couldn’t be truer. Traditional machining methods take more time because they require manual operation. Workers have to constantly measure, adjust, and fine-tune. But with CNC lathe machines, it’s all automated. Once the program is set, the machine can run continuously, even 24/7 if needed. This means faster production times and higher output—without sacrificing quality.

CNC lathe machines aren’t just one-trick ponies. They can handle a wide range of materials and perform various operations, from turning and drilling to threading and knurling. Whether you’re working with metals like aluminum or steel, or more delicate materials like plastics or wood, a CNC lathe machine can handle it all. Need a complex part with multiple dimensions? No problem. CNC lathes can produce intricate shapes that would be near impossible to create manually.

Sure, CNC lathe machines aren’t cheap upfront. But when you think about long-term savings, they’re worth every penny. With reduced human error and faster production times, companies can save on material costs and labor. Plus, since CNC lathe machines can operate continuously, they can significantly boost production without needing more workers on the floor. Over time, the machine pays for itself in efficiency and productivity gains.

When you’re manufacturing parts, especially in industries like aerospace or automotive, consistency is key. A part that’s off by even a millimeter could lead to disastrous results. CNC lathe machines deliver the same quality every single time. Whether you're making 10 parts or 10,000, you get identical, high-quality products. This kind of consistency is vital in industries that rely on precision-engineered parts.

Mistakes can be costly, especially when working with expensive materials. With traditional machining, there’s a higher chance of human error, leading to wasted materials. CNC lathe machines significantly reduce waste. Since the computer controls every movement, there’s far less room for mistakes. The accuracy of CNC machines ensures that every cut is exactly as it should be, maximizing material usage and minimizing waste.

Manufacturing can be dangerous, especially when heavy machinery and sharp tools are involved. However, CNC lathe machines enhance safety by reducing the need for manual intervention. Operators aren’t directly handling the materials or tools, which means fewer accidents. Plus, the machines come with safety features like automatic shutdowns in case of malfunctions. In an industry where safety is a top priority, CNC lathes help keep workers out of harm’s way.

CNC lathes are commonly used in a variety of industries, such as:

Automotive: Precision parts for engines and transmissions.

Aerospace: Components that require strict tolerance and durability.

Medical devices: Creating complex instruments and implants.

While both CNC and conventional lathes serve the same function, there are significant differences:

Conventional lathes require hands-on operation, while CNC lathes are automated.

CNC lathes provide higher accuracy and repeatability.

CNC machines can run longer without interruption, making them ideal for large-scale production.

The CNC lathe is specially designed to work on larger components, making it an ideal tool for heavy industry applications. These machines often feature a reinforced bed, enhanced motor power, and special tooling options that allow them to handle tougher materials and more substantial workpieces than standard CNC lathes.

Now that we've covered the basics, let's look at the top 10 raised CNC lathe manufacturers leading the market today.

Xiongyi is another major player in the CNC lathe industry. Known for its commitment to quality, the Chinese company offers both high-end Taiwanese-made products and affordable mainland-made products. It is currently expanding rapidly in the global market, providing high-performance lathes suitable for small and large manufacturers.

Key Strengths: High-quality machines, global expansion.

Product Range: CNC lathes, machining centers, automation.

Machine Catalogue Download

Mazak is one of the most recognized names in the CNC industry. Known for their innovation and reliability, Mazak has a strong foothold in the global market, providing advanced multi-tasking CNC lathe solutions.

Key Strengths: Innovative design, energy-efficient machines.

Product Range: Multi-tasking machines, hybrid CNC lathes.

Based in the United States, Haas Automation has a reputation for producing cost-effective yet high-performance CNC lathes. Their customer-friendly approach and vast product range make them a top choice for manufacturers of all sizes.

Key Strengths: Affordable pricing, easy-to-use interfaces.

Product Range: Lathes, mills, and automation systems.

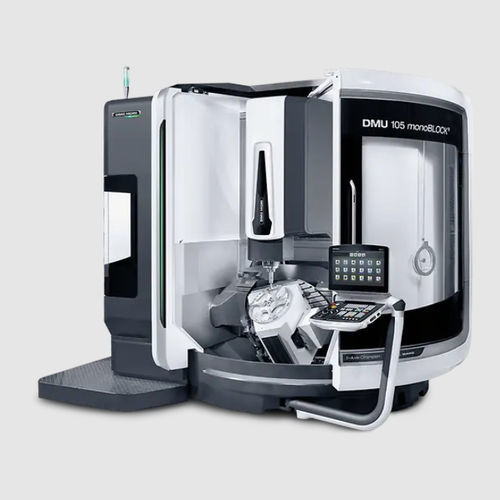

A powerhouse in the CNC world, DMG Mori is known for its cutting-edge technology and comprehensive service network. Their raised CNC lathes are particularly favored for their precision and robustness.

Key Strengths: Global reach, high-precision machines.

Product Range: CNC lathes, milling machines, and automation solutions.

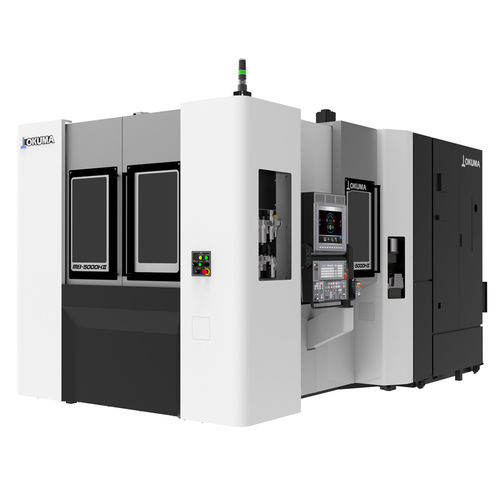

Japanese manufacturer Okuma is renowned for its high-precision CNC machines and dedication to innovation. They specialize in creating CNC lathes that offer reliability and longevity, making them a go-to brand for heavy-duty industrial applications.

Key Strengths: Precision engineering, reliability.

Product Range: CNC lathes, vertical and horizontal machining centers.

Doosan Machine Tools offers a broad selection of CNC lathes tailored to various industry needs. They are known for their continuous innovation and global reach, providing machines that are both powerful and versatile.

Key Strengths: Broad product line, continuous development.

Product Range: CNC lathes, multi-axis machines.

Hurco has made a name for itself by producing intelligent machines that prioritize efficiency. Their raised CNC lathes incorporate advanced control features that reduce setup times and boost productivity.

Key Strengths: Intelligent control systems, user-friendly interfaces.

Product Range: CNC lathes, machining centers.

Tsugami specializes in high-precision CNC lathes, making them the ideal choice for industries that require tight tolerances. Their machines are favored in sectors like medical device manufacturing and aerospace.

Key Strengths: Precision machining, high-quality finishes.

Product Range: CNC lathes, multi-tasking machines.

Known for their compact, high-efficiency machines, Citizen Machinery focuses on producing cost-effective solutions without compromising on quality. Their CNC lathes are especially popular in the production of smaller, intricate parts.

Key Strengths: Compact design, energy-efficient.

Product Range: CNC lathes, Swiss-type automatic lathes.

Rounding out our list is Nakamura-Tome, a Japanese manufacturer that specializes in multi-tasking CNC lathes. Their machines are designed for efficiency, offering multiple functionalities in one package, ideal for complex machining tasks.

Key Strengths: Multi-tasking capabilities, advanced features.

Product Range: Multi-axis CNC lathes, turning centers.

Selecting the right CNC lathe can be a daunting task, given the range of options available. Here are some factors to consider:

It's essential to balance cost and functionality. While some manufacturers may offer feature-packed machines, not all of them might suit your budget. Identify the features you absolutely need and invest in a machine that offers the best value for money.

Another crucial factor is post-purchase support. Manufacturers like Mazak and Haas Automation offer extensive training and support programs that ensure you get the most out of your CNC lathe in the long term.

Choosing the right CNC lathe manufacturer is crucial for ensuring the

success of your manufacturing processes. Whether you prioritize precision, efficiency, or customer support, this list of top manufacturers will help guide your decision-making process. Each company offers unique strengths that cater to different industries, making it easier to find the perfect machine for your needs.

How do I maintain a CNC lathe?

Regular maintenance includes cleaning the machine, inspecting parts for wear, and ensuring proper lubrication of moving components.

Can CNC lathes be customized?

Yes, many manufacturers offer customizable features based on the specific needs of the customer.

Is it worth investing in a multi-tasking CNC lathe?

Multi-tasking CNC lathes are worth the investment if you require versatile operations, as they combine several machining functions into one machine.

content is empty!