Views: 0 Author: Site Editor Publish Time: 2025-10-16 Origin: Site

Hey there! If you're in manufacturing, aerospace, automotive, or any field that demands precision, you've probably heard a lot about 5 axis cnc machine. They're like the Swiss Army knives of machine tools — capable, flexible, and more vital than ever in 2025. In this article, I'll walk you through what these machines are, why they're so in demand, what to watch for when picking a manufacturer — and most importantly, who the top players are right now. Whether you're buying or just staying ahead of tech trends, this will be your go-to guide.

A 5 axis cnc machine is a CNC (Computer Numerical Control) machine that moves a cutting tool or a workpiece in five different axes simultaneously. Typically, besides the standard X, Y, Z linear axes, it includes two rotational ones (often called A and B, or B and C). Imagine carving a sculpture that you can rotate and tilt from all sides without flipping it — that's the power.

Trunnion table: The workpiece sits on a table that can tilt and rotate.

Head/tilting head: The spindle/head moves around the part using rotational axes.

Hybrid designs: A mix of both, offering flexibility in various applications.

Parts are becoming more complex—lightweight structures, organic shapes, more cavities. 5 axis CNC machines let you machine intricate geometries in one setup, drastically reducing errors and improving surface finishes.

Instead of repositioning or re-fixturing a part several times (which eats up time and introduces potential for mistakes), 5 axis CNC machines allow you to handle many faces in a single clamping. That means faster production cycles.

Think aerospace, medical implants, luxury automotive, even electric vehicle components. All pushing tight tolerances, exotic materials, and lighter designs. 5 axis CNC machines meet those needs head-on.

To get the most bang for your buck, you want to make sure your supplier ticks these boxes:

Can the machine hold tolerances within microns? Is repeatability (doing the same cut over and over) reliable? Look for verified specs—manufacturer test data, customer reviews, independent benchmarks.

Even the best machine needs tuning, spare parts, or software updates. A strong support network, readily available replacement parts, and solid training services make all the difference.

In 2025, it's not enough to have a great standalone machine. Can it integrate with robotic loaders, vision systems, IoT monitoring, or even predictive maintenance software? These features drive total productivity upward.

Let me be transparent: here's how I ranked these companies.

Who are the big names that have been delivering five-axis machines globally? Who are customers talking about?

Are they pushing the envelope with new control systems, materials, motion control, or energy efficiency? Patents, R&D investment, tech awards count.

A great machine is useless if you can't get service within a reasonable time or costs are astronomical for shipping parts. Local dealer networks, global support offices matter.

Here are the ten manufacturers you definitely want on your radar. I’ll cover their strengths, what makes them stand out — and maybe a weak point or two.

DMG MORI is a world-leading manufacturer of advanced CNC machine tools, renowned for its precision, innovation, and reliability. Among its product range, the 5 axis cnc machines represent the pinnacle of modern manufacturing technology — combining maximum accuracy, high productivity, and multi-axis flexibility in one system.

Whether in aerospace, medical, automotive, or mold manufacturing, DMG MORI 5-axis machining centers deliver outstanding performance and efficiency for complex part production.

DMG MORI combines German precision engineering with Japanese manufacturing reliability, offering unmatched accuracy, rigidity, and stability. Every component is designed for maximum performance and long-term durability.

Rigid monoblock machine bed ensures minimal vibration.

Direct-drive motors on rotary axes enhance smooth motion and contouring accuracy.

Thermal compensation systems maintain accuracy during long machining hours.

These features make DMG MORI 5-axis machines ideal for tight-tolerance components, such as medical implants or aerospace parts.

With 5-axis simultaneous control, users can machine all sides of a workpiece in one clamping, reducing setup time and improving repeatability. This greatly enhances productivity for complex geometries, freeform surfaces, and multi-face machining.

DMG MORI integrates CELOS — its intelligent, user-friendly CNC interface — allowing operators to:

Monitor machining conditions in real time

Optimize tool paths and reduce idle times

Connect with ERP and MES systems for smart manufacturing

This makes DMG MORI a leader in digitalized production and Industry 4.0 integration.

DMG MORI offers a complete lineup of 5-axis machining centers to meet diverse industry demands:

DMU Series – High-performance universal 5-axis machining centers

DMF Series – Long-travel machines for large workpieces

DMU eVo Series – Compact and high-speed models for precision applications

DMC Series – High-rigidity machines for heavy-duty cutting

DMG MORI 5-axis machining centers are widely used across industries requiring precision and efficiency:

Aerospace – Turbine blades, structural components, and housings

Medical – Implants, bone screws, and surgical instruments

Automotive – Engine blocks, transmission housings, and die molds

Mold & Die – Complex cavity surfaces and precision molds

Each application benefits from DMG MORI's precision, rigidity, and digital control technology.

DMG MORI leads the industry in automation and smart factory solutions:

Integrated pallet handling systems (PH Cell, Robo2Go)

CELOS IoT integration for predictive maintenance

These systems allow manufacturers to achieve unmanned production, higher uptime, and consistent quality.

DMG MORI stands as a benchmark for high-end 5-axis machining technology, empowering manufacturers to achieve greater accuracy, shorter lead times, and higher productivity.

Conclusion

The DMG MORI 5-axis machining center represents the future of precision manufacturing. By integrating intelligent software, high-performance mechanics, and automation-ready design, DMG MORI continues to redefine productivity and quality standards in modern CNC machining.

If your business demands complex part machining, tight tolerances, and continuous operation efficiency, DMG MORI's 5-axis machining centers are the ultimate solution.

Haas Automation is one of the most trusted CNC machine tool manufacturers in the world, known for delivering high-performance, reliable, and cost-effective solutions for precision manufacturing.

Among its product lineup, the Haas 5-Axis Machining Centers stand out as a perfect combination of power, accuracy, and ease of use, helping manufacturers produce complex parts efficiently and affordably.

Whether you’re machining aerospace components, automotive molds, or precision medical parts, Haas 5-axis machines are engineered to deliver exceptional results with American-built quality.

A 5-axis machining center allows the cutting tool or the workpiece to move in five different axes simultaneously — X, Y, Z, and two rotational axes (A and B).

This advanced motion control enables complex and multi-sided machining in one setup, minimizing manual repositioning, increasing accuracy, and boosting productivity.

Haas integrates this technology into its machines to make 5-axis machining simple, affordable, and accessible for every workshop.

Every Haas 5-axis machining center is designed, built, and tested in the USA.

This ensures superior quality control, robust machine design, and long-term reliability that customers worldwide have come to trust.

With Haas, you get premium performance at a competitive price.

Haas has made 5-axis machining easy to learn and operate, thanks to its intuitive Haas CNC control.

The system includes:

Dynamic Work Offsets (DWO)

Tool Center Point Control (TCPC)

These technologies simplify programming by allowing the operator to program parts without worrying about the part’s exact position on the table — saving hours of setup and adjustment time.

Heavy-duty cast iron base ensures excellent rigidity and vibration damping.

High-performance spindle systems deliver strong torque and smooth cutting.

Advanced servo control ensures tight tolerances even during high-speed motion.

This makes Haas 5-axis machining centers ideal for high-precision, multi-surface machining in aerospace, energy, and mold industries.

Haas offers automation-ready designs, including:

Automatic Pallet Changers (APC)

Haas Robot Packages

Wireless Intuitive Probing System (WIPS)

These systems allow manufacturers to achieve lights-out machining, improving productivity without sacrificing accuracy — at a much lower cost than comparable European or Japanese brands.

Haas provides a broad lineup of 5-axis solutions tailored to different production needs:

UMC Series – Universal Machining Centers for high flexibility and precision.

EC-1600ZT-5AX – Large-travel, heavy-duty 5-axis machine for big parts.

Mini Mill 5AX – Compact and affordable solution for small parts and prototyping.

Each model is designed for different part sizes, industries, and production volumes, giving customers full flexibility.

Haas 5-axis machines are used in a wide range of industries that demand accuracy, efficiency, and surface finish:

Aerospace: turbine components, impellers, and housings

Automotive: engine blocks, molds, and precision parts

Medical: dental implants, bone screws, and surgical tools

Energy and Tooling: complex molds and dies

These machines allow users to complete complex parts in a single setup, improving throughput and consistency.

The Haas Next Generation Control (NGC) system is designed for smart manufacturing environments:

Easy networking and data exchange

Real-time toolpath visualization

Remote machine monitoring

Integration with CAD/CAM systems

Together, these features make Haas 5-axis machining centers fully compatible with Industry 4.0 and digitalized production.

✅ American-built quality and durability

✅ Affordable entry into 5-axis machining

✅ User-friendly control with powerful features

✅ Broad model range for any production scale

✅ Global service and support network

Haas Automation brings 5-axis technology within reach of every manufacturer, combining simplicity, reliability, and innovation — all built in the USA.

The Haas Automation 5-Axis Machining Centers redefine the balance between performance, precision, and price.

Designed for modern workshops, these machines deliver high accuracy, multi-axis flexibility, and seamless automation — empowering manufacturers to stay competitive in today's precision-driven industries.

If you’re looking for a reliable, cost-effective, and easy-to-use 5-axis CNC solution, Haas Automation is your trusted partner in advanced manufacturing.

Mazak Corporation, headquartered in Japan and a global leader in CNC machine tool manufacturing, is synonymous with precision, innovation, and reliability.

Its 5-axis machining centers represent the forefront of advanced manufacturing technology — integrating multi-axis flexibility, intelligent automation, and digital connectivity to meet the complex demands of modern industries.

Mazak’s 5-axis machining solutions empower manufacturers to produce high-precision components in fewer setups, improving efficiency and competitiveness in aerospace, automotive, energy, and medical industries.

Mazak machines are engineered and built with the legendary Japanese commitment to precision and craftsmanship.

Every component — from spindle systems to control architecture — is optimized for maximum rigidity, stability, and reliability, ensuring consistent accuracy even in heavy-duty operations.

Mazak 5-axis centers enable complete machining of complex parts in a single clamping.

This dramatically shortens setup time and improves geometric accuracy — ideal for aerospace, mold, and energy applications where micron-level precision matters.

Robust machine bed and trunnion-table configuration ensure excellent rigidity and vibration absorption.

High-speed, high-torque spindle options (up to 20,000 rpm) deliver superior cutting performance for titanium, aluminum, and stainless steel.

Intelligent thermal control maintains accuracy during long production cycles.

Mazak’s proprietary MAZATROL SmoothX CNC control system revolutionizes the way 5-axis machining is performed.

It offers:

Simplified 5-axis programming with intuitive conversational interface

Dynamic machine simulation for safe and efficient setup

AI-based adaptive control for real-time toolpath optimization

The SmoothX platform integrates seamlessly with Mazak’s iSMART Factory™ for full digital connectivity and Industry 4.0 readiness.

Mazak provides a comprehensive range of 5-axis machining centers designed for diverse applications:

VARIAXIS Series – Compact, high-speed 5-axis centers for complex precision components

INTEGREX Series – Multi-tasking machining centers combining turning, milling, and 5-axis capabilities

VC-500A/5X and CV5-500 – Affordable entry-level 5-axis solutions for small to medium workshops

VARIAXIS i-Series – Designed for continuous 5-axis contouring and heavy cutting

Each series delivers the perfect balance of speed, rigidity, and flexibility, optimized for both prototyping and full-scale production.

Mazak 5-axis technology is widely used in high-precision and high-value manufacturing fields:

Aerospace – turbine blades, airframe components, impellers

Automotive – mold tools, engine housings, and transmission parts

Medical – surgical instruments, implants, and prosthetics

Energy & Tooling – turbine components and complex dies

By enabling simultaneous multi-surface machining, Mazak machines reduce part handling and improve overall throughput.

Mazak leads the CNC industry in automation and smart factory integration.

Its systems support:

Robotic loading/unloading systems

PALLETECH automation systems

iSMART Factory™ connectivity for real-time data tracking

AI-based machine learning for predictive maintenance

These technologies help manufacturers achieve unmanned production, higher uptime, and lower operational costs, aligning with global smart manufacturing trends.

✅ Japanese engineering with global innovation

✅ High accuracy and rigidity for complex parts

✅ Intelligent SmoothX control for easy 5-axis programming

✅ Seamless automation and digital factory integration

✅ Global service and training network

Mazak continues to set the benchmark in 5-axis machining, empowering industries worldwide with cutting-edge solutions that maximize productivity, quality, and reliability.

The Mazak 5-Axis Machining Centers embody the perfect combination of precision engineering, smart control, and automation flexibility.

By enabling single-setup machining, intelligent process control, and full Industry 4.0 connectivity, Mazak provides manufacturers with the tools to achieve faster cycles, higher accuracy, and lower costs — all while future-proofing their production lines.

If you are seeking world-class 5-axis CNC performance, Mazak Corporation is your trusted partner in advanced manufacturing.

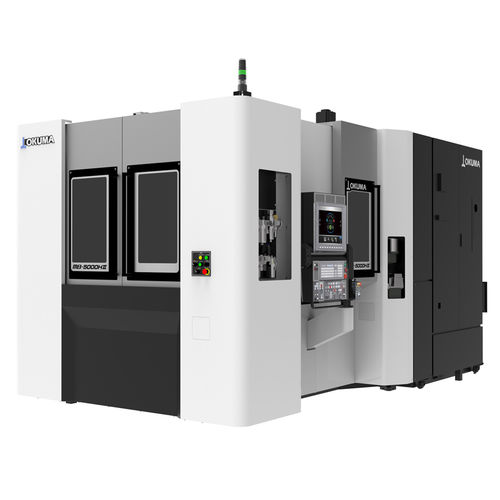

Okuma Corporation, founded in Japan, is one of the world’s leading CNC machine tool manufacturers, known for its precision engineering, high reliability, and smart control systems.

The company’s 5-axis machining centers represent a perfect combination of accuracy, rigidity, and intelligent technology, designed to meet the demanding requirements of aerospace, automotive, die/mold, and medical industries.

With its proprietary OSP control system, robust machine construction, and advanced thermal compensation, Okuma 5-axis machining centers deliver long-term accuracy and stable productivity — the hallmarks of Japanese manufacturing excellence.

Okuma's exclusive Thermo-Friendly Concept technology minimizes thermal distortion during long machining operations.

By controlling temperature variations across the spindle and structure, the machine maintains stable dimensional accuracy — even under continuous production conditions.

This makes Okuma's 5-axis centers ideal for precision machining environments.

Solid cast-iron base for superior vibration damping and rigidity.

Optimized trunnion and spindle design for smooth 5-axis motion.

Excellent chip evacuation for clean and efficient cutting.

Okuma's mechanical design ensures stability and repeatable accuracy, even during heavy-duty cutting operations.

Okuma's self-developed OSP Control System is one of the industry's most advanced CNC platforms.

It provides:

Intuitive 5-axis programming and real-time simulation.

AI-based tool load monitoring for predictive maintenance.

Collision avoidance system for safe multi-axis machining.

Seamless connection with smart factory and IoT systems.

With OSP, Okuma brings intelligence and automation directly into the machining process.

Okuma offers a full range of 5-axis machining centers to meet different production requirements:

MU Series – Universal 5-axis vertical machining centers with high flexibility.

MB-80V/5AX – Large-capacity 5-axis machining center for big workpieces.

GENOS M460V-5AX – Compact, cost-effective 5-axis model for small precision parts.

Each model is designed for maximum productivity, whether for small shops or large-scale industrial operations.

Okuma integrates robotic automation, pallet handling systems, and intelligent monitoring solutions to achieve efficient, unmanned production.

Through OSP Smart Factory integration, users can monitor machine performance, analyze tool wear, and optimize cycle time — all from a connected digital platform.

This supports Industry 4.0 and enables real-time production control.

Okuma 5-axis machining centers are trusted worldwide across industries requiring complex geometries and high precision:

Aerospace – turbine blades, impellers, and engine housings

Automotive – molds, precision transmission, and engine components

Medical – orthopedic implants, dental parts, surgical instruments

Energy and Tooling – large molds and high-performance dies

Each Okuma machine ensures excellent surface finish, dimensional consistency, and reliable long-term performance.

✅ Japanese precision and reliability

✅ Thermo-Friendly Concept ensures long-term accuracy

✅ High rigidity for stable and heavy-duty machining

✅ Smart OSP Control with AI monitoring and collision prevention

✅ Flexible model range from compact to large-scale applications

✅ Full automation and smart factory compatibility

Okuma stands as a trusted brand for manufacturers seeking accuracy, reliability, and intelligent CNC solutions in 5 Axis Cnc Machine .

The Okuma 5 Axis Cnc Machine embody the company's long-standing philosophy — “Open Possibilities.”

With superior thermal stability, robust structural design, and intelligent OSP control, Okuma provides manufacturers with unmatched precision and performance for today's competitive market.

Whether for aerospace, automotive, or medical components, Okuma's 5-axis machines deliver the stability, intelligence, and productivity that define the next generation of smart manufacturing.

Hurco Companies, Inc., founded in 1968 in the United States, is globally recognized as a pioneer in CNC control technology and high-performance machining centers.

Hurco's 5 Axis Cnc Machine combine precision engineering with advanced control systems to deliver fast, flexible, and intelligent machining solutions for complex components.

Whether producing aerospace parts, molds, or medical components, Hurco’s 5-axis machines are designed to help manufacturers increase productivity, reduce setup time, and achieve superior accuracy — all while maintaining user-friendly operation.

Hurco's proprietary WinMax® control is one of the most user-friendly CNC systems on the market.

It features:

Conversational programming — easy to learn, no G-code expertise required.

Solid model import directly from CAD files.

Real-time 3D simulation to prevent programming errors.

NC/Conversational hybrid programming for ultimate flexibility.

With WinMax, even complex 5-axis parts can be programmed in minutes, not hours.

Hurco designs its machines with robust cast-iron frames and thermal-stable structures, ensuring high rigidity and vibration control.

This allows the machine to handle heavy cuts with consistent precision, even under demanding conditions.

High-quality components such as spindle bearings, linear guideways, and direct-drive rotary tables contribute to long-term accuracy and durability.

Hurco offers a broad lineup of 5-axis machining centers to suit different production needs:

VCX600i/VCX600iSR – Compact vertical 5-axis models for precision small parts.

U-Series (U30i, U40i, U65, U1000) – Trunnion-style 5-axis machines ideal for multi-sided machining.

BX-Series – Double-column bridge-type design for large and heavy workpieces.

Each model is designed for speed, flexibility, and superior accuracy.

Hurco integrates automation-ready designs for robotic systems, pallet changers, and tool monitoring.

Its control system supports Ethernet connectivity, Industry 4.0 integration, and remote monitoring, allowing manufacturers to improve workflow and reduce downtime.

This connectivity transforms Hurco machines into smart manufacturing solutions ready for the digital factory era.

Hurco's 5-axis machining centers are engineered to reduce setup and cycle time.

By completing multiple operations in one setup, users can:

Eliminate manual repositioning.

Improve accuracy across multiple surfaces.

Reduce overall machining time by up to 50%.

Increase part consistency for complex geometries.

These advantages make Hurco a strong partner for high-mix, low-volume manufacturing environments.

Hurco's 5 Axis Cnc Machine are widely used across diverse industries, including:

Aerospace: turbine blades, engine components, structural parts.

Automotive: molds, dies, precision transmission housings.

Medical: orthopedic implants, dental parts, surgical instruments.

Tool & Die: complex cavities and high-precision molds.

Their ability to deliver repeatable precision and excellent surface finishes makes Hurco machines ideal for advanced manufacturing needs.

✅ User-friendly WinMax control with conversational programming

✅ Strong mechanical rigidity and long-term accuracy

✅ Versatile model lineup for various industries and part sizes

✅ Fast setup and reduced machining time

✅ Automation-ready and Industry 4.0 compatible

✅ Reliable U.S. engineering with global service network

Hurco's blend of innovation, usability, and precision makes it a preferred choice for manufacturers who demand both flexibility and performance.

Hurco 5 Axis Cnc Machine redefine smart and flexible manufacturing.

With their intuitive WinMax control system, robust mechanical design, and integrated automation capabilities, Hurco empowers manufacturers to boost efficiency, shorten lead times, and deliver superior quality.

For businesses seeking a reliable and innovative 5-axis CNC solution, Hurco Companies stands as a trusted global partner — bringing together American innovation and world-class performance.

Makino Milling Machine Co., Ltd., founded in Japan in 1937, is globally recognized as a leader in precision machining and advanced manufacturing technology.

Makino's 5 Axis Cnc Machines are designed to deliver unmatched accuracy, surface finish, and productivity, setting the standard for high-end industries such as aerospace, automotive, medical, and die/mold manufacturing.

Combining Japanese precision craftsmanship with cutting-edge digital control, Makino's 5 Axis Cnc Machine empower manufacturers to achieve ultra-precision machining, reduced setup times, and superior process reliability — essential qualities in modern high-performance manufacturing.

Makino machines are renowned for their nanometer-level precision.

Through innovations such as:

Super Geometric Intelligence (SGI.5) for ultra-smooth motion control,

Thermal stability technology for temperature compensation, and

Rigid machine construction for vibration control,

Makino achieves exceptional dimensional accuracy and mirror-like surface finishes, even during long, complex machining operations.

Makino's core cooling technology and intelligent thermal control systems maintain consistent temperature throughout the spindle and machine frame.

This minimizes thermal growth and distortion, ensuring repeatable accuracy over extended production runs — a critical factor in aerospace and die/mold industries.

Equipped with high-speed spindles (up to 33,000 rpm) and optimized servo systems, Makino 5 Axis Cnc Machines deliver:

Faster cycle times

Smoother toolpaths

Excellent contouring precision

Longer tool life

These capabilities make Makino ideal for high-performance materials such as titanium, Inconel, aluminum alloys, and hardened steel.

Makino's proprietary Professional 6 (Pro6) control system enhances operator productivity and confidence with:

Intuitive touchscreen interface

Data-driven process optimization

Real-time 3D simulation and collision avoidance

Automatic toolpath optimization with AI algorithms

The Pro6 combines intelligent control and process monitoring, enabling maximum utilization of 5-axis capabilities while maintaining safety and efficiency.

Makino provides a comprehensive selection of 5 Axis Cnc Machines to suit diverse production needs:

D-Series (e.g., D200Z, D300, D500) – Compact vertical 5-axis machines for high-precision die/mold applications.

DA and T-Series – Ideal for high-speed machining of aerospace and complex parts.

a500Z / a800Z – Horizontal 5-axis machining centers built for productivity and versatility.

Each model is designed for rigidity, speed, and precision, ensuring consistent performance across a wide range of part sizes and materials.

Makino offers robotic automation systems, pallet changers, and cell control software for continuous, unmanned production.

Through MAS-A5 automation and IoT connectivity, users can:

Monitor real-time performance data

Predict maintenance needs

Optimize tool life and scheduling

This transforms Makino’s 5-axis machining centers into a complete smart manufacturing ecosystem — ready for Industry 4.0 integration.

Makino 5 Axis Cnc Machines are trusted by top-tier manufacturers in:

Aerospace – turbine blades, impellers, and structural titanium parts

Automotive – engine components, transmission cases, and molds

Medical – orthopedic implants, dental instruments, and surgical tools

Die/Mold – high-precision cavities, injection molds, and stamping dies

Their superior precision, rigidity, and reliability ensure high productivity and long-term performance in the most demanding industries.

✅ Japanese precision and world-class craftsmanship

✅ Super Geometric Intelligence (SGI.5) for ultra-smooth cutting

✅ Thermal stability for long-term accuracy

✅ High-speed spindles and efficient servo control

✅ Professional 6 control with intuitive, data-driven operation

✅ Automation-ready and Industry 4.0 compatible

Makino's 5-axis machining centers deliver maximum performance, reliability, and digital intelligence — empowering manufacturers to reach new levels of precision and efficiency.

Makino Milling Machine Co. continues to set benchmarks in precision and innovation.

Its 5 Axis Cnc Machines embody the perfect balance of speed, accuracy, and intelligent control, enabling manufacturers to produce the world's most complex parts with confidence.

From aerospace to die/mold production, Makino's 5 Axis Cnc Machines are more than just tools — they are the foundation of next-generation precision manufacturing.

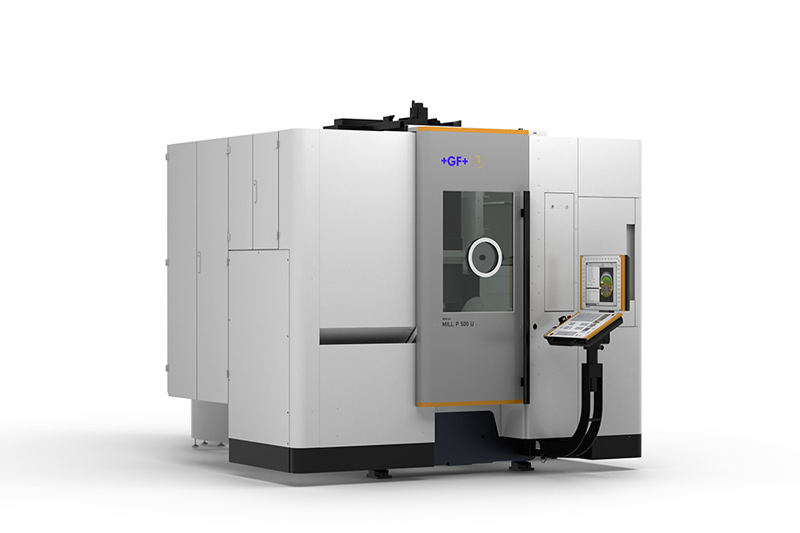

GF Machining Solutions, a division of the Swiss-based Georg Fischer Group (GF), is a world leader in high-precision machining technologies.

With a history of innovation and excellence, GF provides manufacturers with 5-axis machining centers that deliver unmatched accuracy, performance, and surface quality for the most demanding industries — including aerospace, automotive, medical, and mold & die manufacturing.

The company's advanced Mikron series 5-axis machining centers combine Swiss precision engineering, thermal stability, and intelligent digital control to help manufacturers achieve maximum productivity and repeatability in every operation.

GF Machining Solutions has long been synonymous with Swiss craftsmanship.

Its 5 Axis Cnc Machines offer:

Ultra-precise spindle technology with speeds up to 42,000 rpm.

Submicron accuracy for tight tolerances and fine detail.

Superior surface finishes ideal for mold, die, and optical components.

These features ensure consistent quality in high-precision and micro-machining applications.

Temperature fluctuations are one of the main causes of dimensional inaccuracy.

GF's machines are engineered with optimized cooling systems and rigid cast-iron structures to maintain thermal stability throughout long machining cycles.

The result: stable accuracy, minimal distortion, and consistent quality, even during extended operations or high-speed cuts.

GF's Mikron 5-axis machining centers are designed for both speed and power.

Mikron MILL S Series – High-speed machining for complex small parts.

Mikron MILL E Series – Flexible, cost-effective performance for medium production.

Mikron MILL P Series – High-performance cutting for large molds and aerospace components.

Whether machining aluminum, steel, titanium, or composite materials, GF machines ensure superior chip evacuation, dynamic acceleration, and long-term reliability.

GF's numerical control system integrates with smart manufacturing solutions to optimize workflow and minimize downtime.

Features include:

Smart Machine Modules for real-time monitoring and adaptive control.

Toolpath optimization algorithms for smoother 5-axis motion.

Machine connectivity for Industry 4.0 through GF’s rConnect digital platform.

Remote machine diagnostics and predictive maintenance.

This digital intelligence enables smarter, more autonomous production environments.

GF Machining Solutions leads in automation and process integration.

Through its modular automation platforms, such as System 3R and WorkPartner 1+, users can integrate:

Robotic tool changers

Automatic pallet handling

Unmanned night and weekend production

These automation solutions maximize machine uptime, reduce labor costs, and enhance overall productivity.

GF Machining Solutions 5 Axis Cnc Machines are trusted worldwide for applications that demand complex geometries and extreme precision:

Aerospace: turbine blades, structural components, and titanium parts

Automotive: precision molds, injection dies, and engine components

Medical: implants, dental prosthetics, surgical instruments

Tool & Die: high-finish molds, cavity details, and high-tolerance dies

Optical Components: mirror-polished surfaces and fine features

Each GF machine is built to ensure precision, consistency, and superior surface quality across industries.

✅ Swiss precision engineering for ultimate accuracy

✅ Thermally stable design for long-term repeatability

✅ High-speed spindle and efficient chip removal

✅ Smart digital integration via rConnect

✅ Flexible automation for lights-out production

✅ Proven reliability for aerospace, medical, and die/mold industries

GF's 5 Axis Cnc Machines provide the perfect balance between precision, speed, and intelligence, empowering manufacturers to achieve higher performance and profitability.

GF Machining Solutions continues to redefine precision manufacturing with its advanced 5 Axis Cnc Machines.

Built on Swiss innovation, thermal stability, and smart digital control, GF machines deliver exceptional part quality, reduced cycle time, and maximum reliability.

Whether for aerospace components, molds, or micro-precision parts, GF's 5 Axis Cnc Machines enable manufacturers to go beyond traditional limits — achieving true precision excellence.

Beijing Jingdiao Group is a leading Chinese manufacturer specializing in high-speed precision CNC machining centers, well-known for its innovation in 5-axis simultaneous machining and micro-milling technology. Founded in 1994, Jingdiao has become a global name in ultra-precision machining, combining high-speed spindles, advanced control systems, and intelligent software to achieve world-class results.

Jingdiao's 5 Axis Cnc Machines are widely used in industries such as aerospace, medical equipment, automotive molds, watchmaking, and consumer electronics, where extremely fine surface finish and dimensional accuracy are essential.

Beijing Jingdiao machines are engineered for micron-level precision.

The high-speed spindle and rigid frame deliver outstanding accuracy and minimal vibration, even at ultra-high feed rates.

The surface roughness can reach Ra ≤ 0.05 μm, achieving mirror-like finishes.

Ideal for industries requiring fine detail machining, such as jewelry, optical lenses, and precision molds.

Unlike most competitors, Jingdiao develops its own CNC controller and CAM software.

The JDSoft CNC System ensures seamless data flow between CAD/CAM and machine execution.

Intelligent path optimization and dynamic feed control enable smooth 5-axis interpolation.

This in-house integration enhances system stability, machining accuracy, and user control flexibility.

Jingdiao's 5-axis centers combine lightweight motion structures with rigid machine construction.

Linear motor drives and high-speed rotary tables deliver rapid yet stable positioning.

The machine’s thermal stability system minimizes deformation during long machining cycles.

These features ensure consistent performance for both hard materials (steel, titanium) and soft materials (aluminum, resin).

Beijing Jingdiao incorporates advanced intelligent error compensation and automatic measurement systems.

The machine automatically adjusts for tool wear and temperature drift.

Built-in probes and sensors maintain consistent machining accuracy without manual intervention.

The result is a smart, self-learning machining process ideal for precision manufacturing.

Beijing Jingdiao's 5 Axis Cnc Machines are designed for complex geometry machining and ultra-fine detailing across multiple industries:

Aerospace: turbine blades, impellers, engine components

Medical: dental implants, surgical tool parts

Mold & Die: micro molds for injection and precision tooling

Watch & Jewelry: micro components and decorative precision cuts

Consumer Electronics: smartphone frames, molds for camera lenses

Micron-level precision and ultra-smooth surfaces

Self-developed CNC and software ecosystem

High-speed spindle with exceptional rigidity

Thermal compensation and intelligent calibration

Compact design suitable for high-precision workshops

Ideal for micro-machining and fine component production

The Beijing Jingdiao 5-axis machining centers stand at the forefront of precision manufacturing technology, offering a complete in-house solution that integrates machine design, control software, and intelligent operation.

With superior accuracy, stable performance, and advanced digital control, Jingdiao provides manufacturers with the perfect balance between speed, precision, and reliability. For businesses aiming to push the boundaries of surface quality and micro-detailing, Beijing Jingdiao represents the future of precision machining.

Litz Machinery, a leading Taiwanese manufacturer, specializes in high-precision CNC machining centers, with a focus on 5-axis simultaneous machining. Renowned for combining rigid mechanical construction, high-speed spindles, and advanced control systems, Litz provides solutions that meet the demands of global manufacturers.

Litz 5 Axis Cnc Machines are widely used in industries such as aerospace, automotive, medical devices, mold & die, and electronics, where precision, surface quality, and efficiency are critical.

Litz 5-axis machines are designed for micron-level accuracy:

Rigid machine frames and high-quality spindles reduce vibration for stable and precise cutting.

Achievable surface finishes as low as Ra ≤ 0.05 μm, ideal for molds, medical components, and aerospace parts.

Thermal compensation ensures repeatable precision even during long production cycles.

Litz integrates advanced CNC controllers (FANUC, Siemens, or proprietary systems) to optimize machining performance:

Simultaneous 5-axis interpolation enables complex geometries and multi-sided machining in a single setup.

Intelligent toolpath optimization reduces machining errors and shortens cycle times.

User-friendly interfaces support both conversational programming and G-code operation, enhancing operator efficiency.

Litz 5 Axis Cnc Machines combine high-speed motion systems with robust mechanical design:

Spindle speeds up to 24,000 rpm support both roughing and finishing operations.

Linear guideways and precision ballscrews ensure smooth and accurate motion.

Thermal stability and vibration damping maintain consistent accuracy over long machining cycles.

Litz 5-axis machines are designed for modern smart factories:

Support for robotic loaders, pallet changers, and lights-out operation allows unmanned production.

Built-in sensors monitor spindle and machine health for predictive maintenance.

Intelligent error compensation ensures consistent part quality across production batches.

Litz 5 Axis Cnc Machines are ideal for complex and precision-critical components across industries:

Aerospace: turbine blades, impellers, engine components

Automotive: molds, engine blocks, transmission parts

Medical: implants, surgical instruments, dental devices

Die & Mold: precision molds and high-finish cavities

Electronics: housings, connectors, micro components

Litz machines provide consistent quality, high efficiency, and flexibility, suitable for both high-mix, low-volume and mass production operations.

Micron-level precision with superior surface finish

Rigid construction with high-speed spindle technology

Advanced CNC control with intelligent toolpath optimization

Automation-ready for smart factory environments

Thermal stability for consistent precision

Versatile applications in aerospace, automotive, medical, and mold industries

Litz delivers high-performance yet cost-effective solutions, making its 5-axis machining centers a trusted choice for global manufacturers.

The Taiwan Litz 5 Axis Cnc Machines offer a perfect combination of precision, speed, and intelligent automation. With rigid structures, advanced CNC controls, and automation-ready features, Litz enables manufacturers to produce complex, high-precision parts efficiently and reliably.

For companies seeking high-quality Taiwanese 5-axis machining solutions, Litz stands out as a brand that combines innovation, reliability, and value, meeting the needs of modern manufacturing worldwide.

XIONGYI Company is a premier distributor specializing in high-precision CNC machinery, focusing on 5 Axis Cnc Machines from both Taiwan and China. With years of experience in industrial automation and advanced manufacturing solutions, XIONGYI provides manufacturers worldwide with state-of-the-art 5-axis CNC machines that combine precision, speed, and intelligent control.

XIONGYI represents a range of leading brands, including JINN FA, Leadwell, LiTz, Litz, KEDA, Beijing Jingdiao, and other top Chinese CNC manufacturers, offering machines for industries where accuracy and productivity are paramount.

XIONGYI partners with top Taiwanese and Chinese manufacturers, providing access to machines that are:

High-precision for micron-level machining

High-speed with advanced spindle and drive technology

Reliable and durable, suitable for industrial-scale production

Automation-ready, supporting robotic integration and lights-out manufacturing

By distributing both Taiwanese and Chinese brands, XIONGYI enables customers to choose the best solution based on their production requirements and budget.

The 5 Axis Cnc Machines provided by XIONGYI feature state-of-the-art CNC controllers:

FANUC, Siemens, or proprietary systems for seamless machine control

Simultaneous 5-axis interpolation for complex geometries

Intelligent toolpath optimization and adaptive feed control

User-friendly interfaces supporting both conversational programming and G-code operation

This ensures high precision, reduced cycle time, and smooth operation for complex components.

Machines distributed by XIONGYI are built with rigid frames and high-speed spindles:

Spindle speeds up to 24,000–30,000 rpm for finishing and roughing operations

Linear guides and precision ballscrews for smooth and accurate movement

Thermal stability and vibration damping for consistent accuracy during long cycles

This combination of rigidity and speed allows manufacturers to maintain high productivity while producing complex, high-quality parts.

XIONGYI provides machines that are automation-ready, ideal for modern smart factories:

Compatibility with robotic loaders, pallet changers, and lights-out production

Real-time monitoring and predictive maintenance systems

Intelligent error compensation and tool wear tracking

This enables customers to maximize efficiency, reduce downtime, and maintain part quality across production batches.

The 5 Axis Cnc Machines offered by XIONGYI are widely used across industries that demand high precision and complex geometry machining:

Aerospace: turbine blades, impellers, airframe components

Automotive: molds, engine blocks, transmission components

Medical: implants, surgical instruments, dental devices

Die & Mold: precision molds, high-surface-finish dies

Electronics: housings, connectors, micro components

By providing machines for diverse applications, XIONGYI supports both high-mix, low-volume and mass production environments.

Access to leading Taiwanese and Chinese 5 Axis Cnc Machines

High-performance machines with precision and stability

Advanced CNC control systems for complex machining

Automation-ready solutions for smart manufacturing

Comprehensive support and after-sales service

Tailored solutions to fit diverse industry needs

XIONGYI ensures that manufacturers receive reliable, high-quality 5 Axis Cnc Machines that optimize production efficiency and maintain consistent part quality.

XIONGYI Company is a trusted distributor of Taiwanese and Chinese 5-axis machining centers, providing solutions that combine precision, speed, and intelligent automation. By partnering with leading brands and offering expert guidance, XIONGYI enables manufacturers to achieve higher productivity, superior surface quality, and long-term reliability.

For businesses seeking advanced 5-axis CNC machining centers, XIONGYI is the ideal partner for sourcing top-performing machines from both Taiwan and China.

| Rank | Manufacturer | Country | Key Models | Main Strengths | Innovation Rating (1–10) | Best For |

|---|---|---|---|---|---|---|

| 1 | DMG Mori | Germany/Japan | DMU Series, NMV Series | High precision, digital integration, advanced CELOS software | 10 | Aerospace & Automotive |

| 2 | Mazak Corporation | Japan | VARIAXIS i-Series | Versatile, AI-driven machining, smart factory-ready | 9 | Multi-tasking & Automation |

| 3 | Makino Milling Machine Co. | Japan | D200Z, DA300 | Ultra-precision, excellent thermal control, high speed | 9 | Mold & Die / Aerospace |

| 4 | Okuma Corporation | Japan | MU-5000V, MU-8000V | Stability, rigid structure, strong reliability | 8 | Heavy-duty Cutting |

| 5 | GF Machining Solutions | Switzerland | Mikron MILL P Series | EDM + Milling integration, automation options | 8 | Medical & Tooling |

| 6 | Hurco Companies | USA | VMX42SRTi, VCX600i | User-friendly controls, affordable five-axis entry | 7 | Small Job Shops |

| 7 | Doosan Machine Tools | South Korea | DVF 5000, DVF 6500 | Cost-effective, expanding global network | 7 | General Manufacturing |

| 8 | Haas Automation | USA | UMC-500, UMC-750 | Accessible pricing, easy maintenance | 7 | Entry-level 5-axis users |

| 9 | Taiwan Litz | TAIWAN | LU400 | Excellent automation, smart servo control | 8 | High-speed, light machining |

| 10 | Xiongyi Intelligent Machinery Co. Ltd. | TAIWAN, CHINA | KMU-400PD | Compact, ultra-precise, reliable | 8 | Medical, Micro Parts |

There are companies that specialize in ultra-high precision, exotic materials, custom fixtures. They may not have big global reach, but they may offer solutions your big OEMs don’t.

AI path planning, adaptive tool wear compensation, hybrid additive + subtractive machines – some startups are pioneering this. In a few years, they could shift the landscape.

What materials do you cut? Aluminum? Titanium? Composites? What precision do you need? What part complexity? These questions will narrow your choices.

The sticker price is just the beginning. Think about maintenance, software license fees, energy consumption, training costs. Sometimes a cheaper machine ends up costing more over its lifetime.

Will you need higher speed, more automation, digital monitoring in a few years? If yes, better get a manufacturer who supports upgrades, modular add-ons, or has a culture of tech innovation.

Imagine machining an aircraft wing rib from a single block of titanium. Using a top-tier 5 Axis Cnc Machines from Makino or DMG Mori, with advanced coolant systems and thermal compensation, you can reduce weight, cut lead time, and maintain high fatigue resistance.

For things like knee implants or spinal components: surfaces need to be ultra-smooth, tolerances extremely tight. Kitamura or GF Machining Solutions machines often shine here. With biocompatible materials, micro-finishing, every detail counts.

So, what's the bottom line? 5 Axis Cnc Machines aren't just fancy toys — they're becoming essential tools for anyone serious about precision, complexity, and staying competitive in 2025. Choose your manufacturer wisely: consider precision, support, innovation, and total cost, not just upfront price. Keep your eyes on the innovators and emerging players—you never know who will bring the next breakthrough.

If you liked this deep dive and want comparisons, spec sheets, or what machines are best for your specific industry (aerospace vs medical vs energy), just say the word — I'd love to help you find your perfect match.